3 Impactful Use Cases for Wearable Safety Devices

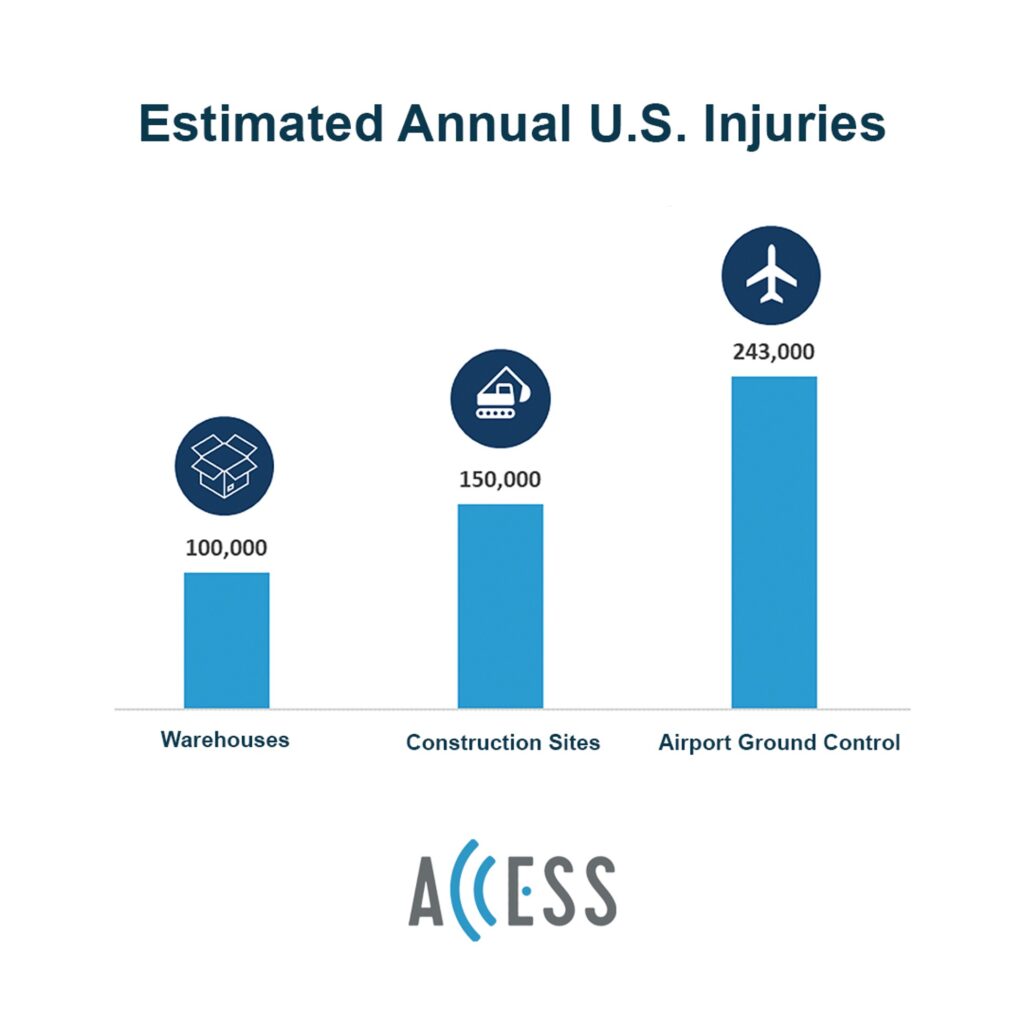

Workplace productivity has become the main priority of most businesses. In the industrial sector, more and more businesses are adopting impressive telematics systems with predictive maintenance and cloud-based analytics. While money is often the motive, many businesses fail to consider the crucial role that workplace safety plays in keeping productivity at an all time high and worker’s compensation claims at an all time low. June 14th marks national forklift safety day. While it is good to get a refresher on the latest safety protocols during this time of year, businesses should consider integrating technologies that can help overcome inevitable human error year around. Follow along as we cover three impactful use cases where businesses are utilizing wearable safety devices to combat workplace injuries (Figure 1).

Figure 1: Estimated U.S. Annual Injuries: Warehouses, Construction Sites, Airport Ground Control

Sources: Safeopedia, Keller & Keller, Flight Safety Foundation

1. Wearable Safety Devices for Warehouses

Heavy machinery, towering pallets, and racing forklifts – warehouses can be a hectic environment to work in. According to EHS Today, “nearly 1 million workplace injuries occur each day in the world.” With such high statistics, it’s important that businesses like warehouse facilities be as proactive as possible in addressing safety. Through the use of smart safety devices on forklifts and wearable safety devices (Figure 2), warehouse workers can be alerted via a buzzer and flashing light if a collision is about to occur. Furthermore, safety devices with GPS can precisely track the location of forklifts and personnel on foot to forewarn of close proximity and thus avoid serious injuries.

Figure 2: Access Control Group’s AWARE safety wearable.

2. Construction Safety Wearables

Construction sites can be a very hazardous environment. Construction companies adopt OSHA protocols and implement fall prevention strategies in an effort to avoid injuries. However, with heavy machinery like large excavators, cranes, and jack hammers all around, there is major room for error. Smart safety devices can be attached to heavy machinery like excavators and paired with wearable devices like necklaces or wrist bands on construction workers on foot. Through integrated GPS, the smart safety devices can measure proximity between machines and workers and even track the location of a worker in case they get hurt in an isolated location.

3. Wearable Safety Technology for Airport Ground Support

Airport ground support equipment (GSE) is at the heart of airport operations. With GSE zooming all around the runway and airplanes flying overhead, there is certainly room for error. Similar to forklifts at warehouses and excavators at construction sites, GSE can also benefit by having smart safety devices anchored to them. Pair the smart safety devices on the GSE with safety wearables on the operators, and airport operations are bound to perform much more smoothly.

The Best Wearable Safety Device for Industrial Environments

Access Control Group (ACG) has over 25 years of expertise in developing feature-rich telematics systems and devices to address safety in rugged work environments. Our ADVANCED fleet management device attaches to any model forklift, construction excavator, or airport GSE to deliver valuable insights like hour meter readings, and maintenance and collision avoidance alerts. When paired with our AWARE smart wearable wristband or necklace, the two work as a comprehensive collision avoidance system that can prevent injuries and save lives. AWARE delivers the following key features:

- Fully configurable alert and alarm ranges

- Easy 30-minute installation

- No calibration required

- Long-lasting, rechargeable batteries

- Compatible with any mobile asset – Brand agnostic

- Compliance with mandated safety regulations

Ready to integrate wearable safety devices at your workplace? Contact Access Control Group to get started.